Situation

GE compressors used for CO2 gas reinjection on the Tupi 4 platform in the Lula oil field off the coast of Brazil

Proven reliablity in CCUS application (EOR) for ten years

GE compressors used for CO2 gas reinjection on the Tupi 4 platform in the Lula oil field off the coast of Brazil

Extreme mechanical load of the compressor seal due to process pressures of up to 428 bar(g) (6,206 PSIG)

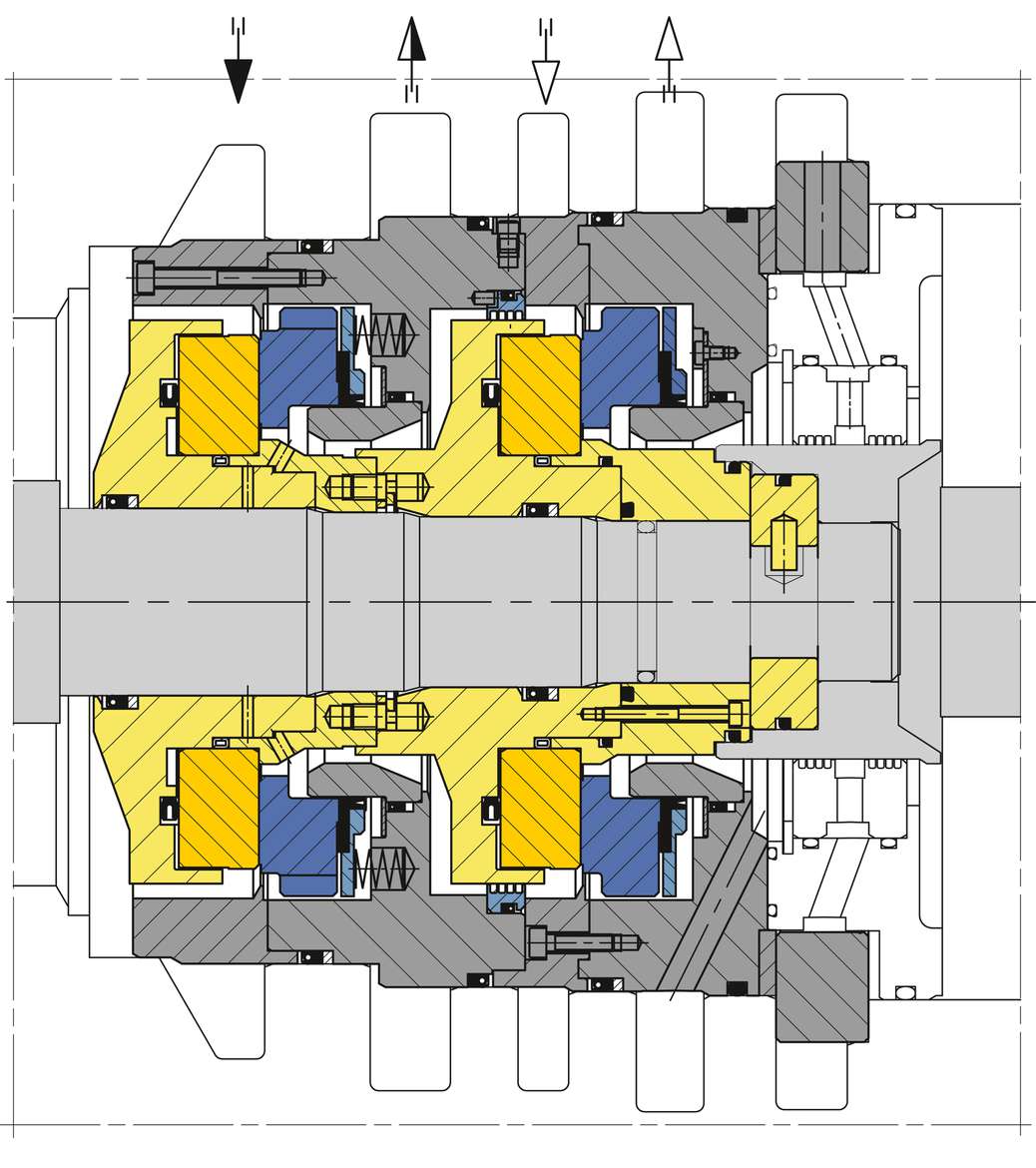

EagleBurgmann tandem PDGS seal with intermediate labyrinth

Discovered in 2006, the Lula oil field is located in the Santos Basin, off the coast of Rio de Janeiro, Brazil, about 250 kilometers to the southwest. The ocean is roughly 2,000 meters deep at this point. The oil and gas-bearing strata lie 4,000-5,000 meters below a layer of rock and salt, called the “pre-salt”. The recoverable oil and gas deposits are estimated at a volume of 5.5 billion barrels. Lula has been tapped into on a large scale since 2008 with FPSO vessels like the Tupi 4.

The deeper below the seabed the drilling is done, the stricter the requirements on rig operators for process pressure to maintain the strong and constant flow of crude oil needed to justify the immense costs of development and license fees. So in this project, every extra bar counts.

The operator, a world leader in the field of CO2 gas reinjection, posed a new challenge for the engineers at EagleBurgmann in 2013. The operating point of the compressors had to reach the unprecedented peak value of 428 bar(g) (6,206 PSIG).

The operating pressure exceeded the limits of all seals used in all ultra-high-pressure applications of this kind to date. The pressure is reached when the system starts up, shuts down, and whenever there is a balance between inlet and outlet pressure at standstill pressure (settle-out pressure). The aim was to create an effective mixing zone needed to bring the crude oil to the production well. The seal also had to be designed for a maximum speed of 13,844 rpm.

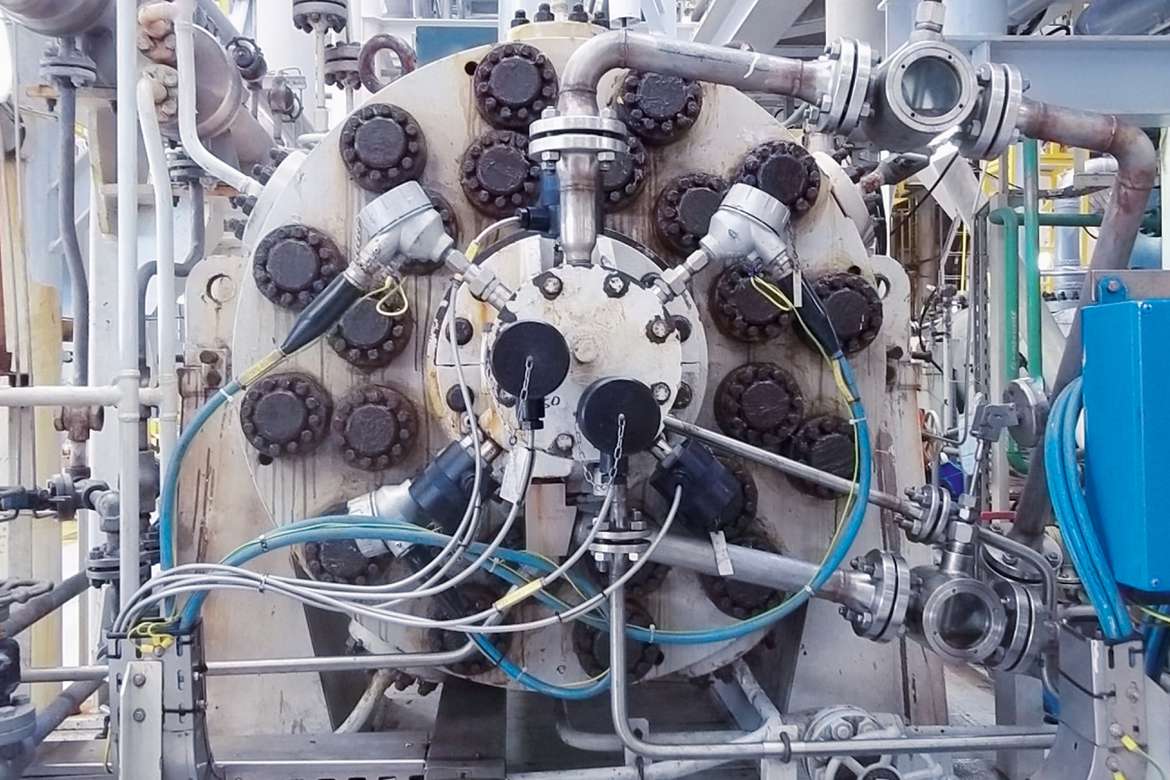

Illustr.: CO2 gas injection compressor at the Tupi 4 FPSO

On the Tupi 4 oil platform, supercritical carbon dioxide (sCO2) is accumulated as an unusable by-product. Since environmental concerns prevent it from being vented to the atmosphere, the operator decided to use the gas as an injection medium. It is therefore injected into the ground instead – and it also poses a more economical alternative to water as an injection medium.

This approach, that is, carbon capture, utilization and storage (CCUS), is considered worldwide to be a major component of a solution for achieving net zero by 2050. This makes CCUS ever more important to reduce the impact of greenhouse gas emissions (GHG).

Illustr. 1: EagleBurgmann PDGS compressor seal (cross-section)

Illustr. 2: Cross-section of a Tupi 4 compressor seal

In developing the seal concept, the engineers at EagleBurgmann opted for the PDGS compressor seal, which was designed for such applications, placing it here in a tandem arrangement with intermediate labyrinth. This arrangement represents the best technical concept for ultra-high process pressures in gas reinjection.

However, several different goals needed to be reconciled when designing the seal to achieve the best possible result. The leakage rate had to be kept as low as possible while keeping the torque stable during start-up. The engineers had three main points to work on to achieve this:

Extensive tests at both the EagleBurgmann R&D center and the compressor manufacturer showed that the seal is extremely reliable during both system start-up and shutdown as well as in continuous operation under full load. The high availability of the compressors is guaranteed alongside minimal leakage in spite of the ultra-high pressure. The outstanding results are also proven in operation.

The performance of the EagleBurgmann PDGS mechanical seal was so convincing that two main and two backup compressors on Tupi 4 have now been equipped with two seals each since the initial installation 10 years ago. The seals were last inspected in 2016. All of them still exhibit top performance values.

The latest qualification of the PDGS series now leads to pressures of up to 650 bar (9427 PSI). The operator is now planning to use the PDGS on further FPSO platforms.

Download the solution flyer

Dry gas seal for multiphase pump applications. The reliable sealing solution for a low vapor margin, flashing hydrocarbons, liquid and supercritical CO2 applications.

Products. Systems. Service.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

By means of custom-made PLUG & RUN expansion joints with a more wear-resistant material, EagleBurgmann was able to provide a solution which ideally fulfills the requirements with regard to wear while at the same time significantly reducing the changeover time.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

Special expansion joints from EagleBurgmann compensate for these position changes and work reliably even under unfavorable conditions such as low temperatures, proximity to the sea and explosive environments.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.