Situation

British Conoco Humber refinery with an annual processing capacity of 85 million barrels of crude oil

MFL65 in hot application up to 400 °C

British Conoco Humber refinery with an annual processing capacity of 85 million barrels of crude oil

Longer operating hours and less leakage during the thermal cracking process

Dual metal bellows seal MFL65-D1/130-E2

The Conoco Humber refinery on the east coast of England has been processing 85 million barrels of crude oil a year since 1969. This means that 230,000 barrels per day are processed mainly into benzin, diesel, kerosene, oil, gas.

One critical area is the thermal cracking process. The crude oil residue is processed at approximately 400 °C, at this temperature it is of low enough viscosity to be pumped effectively. This is handled by a barrel pump on the coker unit.

The originally supplied competitor seals had a service life of approximately three months. The end user asked EagleBurgmann to offer a seal solution with a service life at least twice as long. Leakage from the outboard seal was not allowed to exceed 12 ml/h and a nitrogen purge to prevent coking of the crude oil was not allowed.

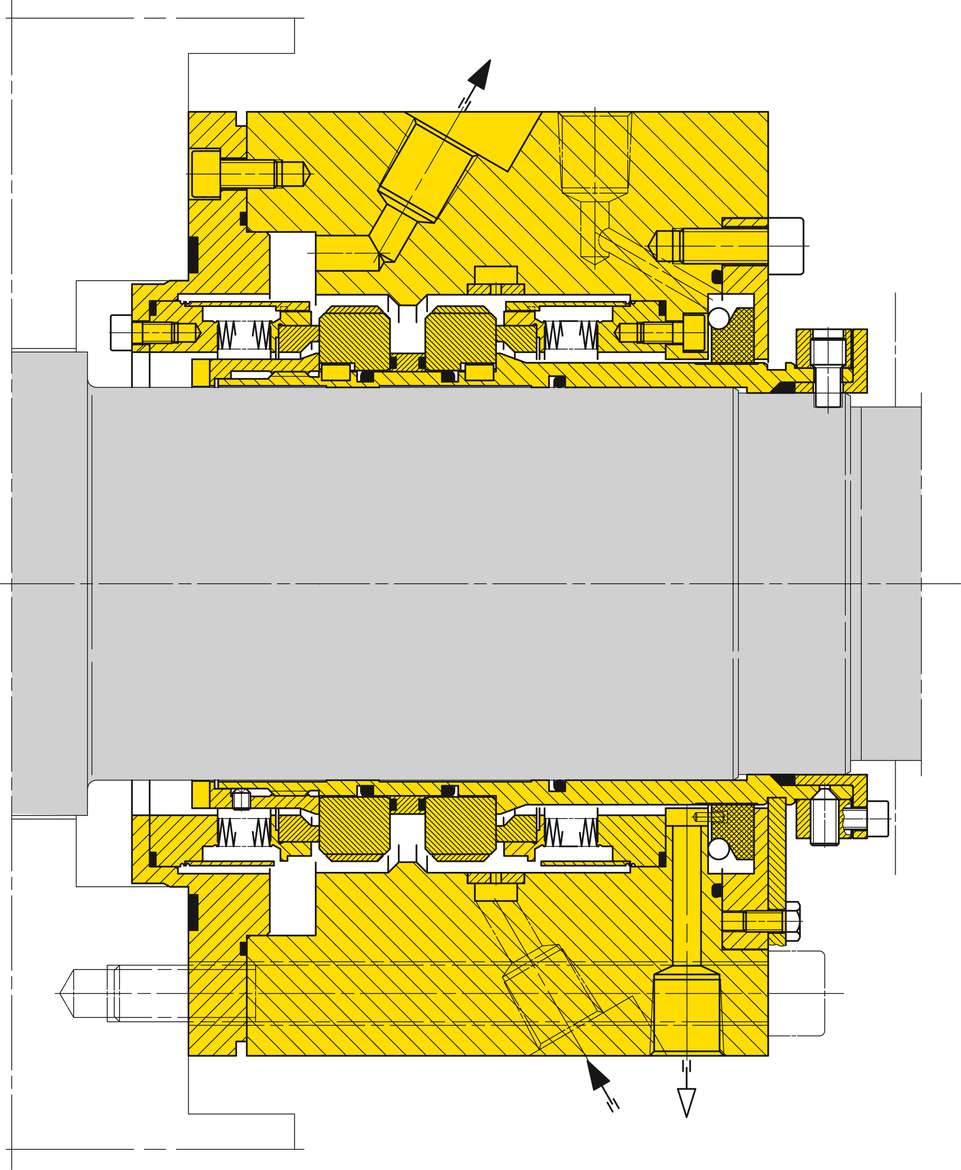

Illustr.: A MFL65 metal bellows seal (stationary unit and counter ring of a single seal) with the typical torque transmission for reducing stress on the bellows.

Selective tests have been run in the EagleBurgmann R&D centre and at the end user‘s facility. This provided the basis for designing and optimizing a mechanical seal able to meet the specific requirements. The answer was the MFL65-D1/130-E2 dual metal bellows seal.

Due to its edge welded metal bellows made of hardened Inconel 718 (2.4668), the seal does not need a dynamically loaded elastomeric O-ring (the temperature resistance of such a ring would be too low in any case for this application).

The secondary seal elements on the in and outboard side are made of high temperature resistant graphite. The elastomers are made of Kalrez. A hard/hard (SiC vs SiC) Q22Q1G/ K1M6T4(1.4462)- Q22Q1G/VM6T4(1.4571) combination was selected for the face materials. Due to security aspects, the silicon carbide rotating seat was changed to a twin seat version.

To be able to meet the specified leakage values and obtain optimum operating characteristics, the sliding faces were improved by minor design enhancements. Also, optimized lubricating grooves were integrated in the sliding faces to guarantee sufficient lubrication without major increase of the leakage rate.

The EagleBurgmann installation satisfied in every respect the requirements imposed by this extremely demanding application. The seals have now been in operation for several years. Running periods are limited only by the two year pump inspections. Leakage is approx. 6 ml/h, half the maximum leakage rate permitted by the customer.

ConocoPhillips have achieved a significant reduction in costs through a drastic increase in the MTBF value and are highly satisfied with the performance of the mechanical seal cartridge. Thanks to the positive results it was decided to convert two remaining pumps to this seal type.

Illustr.: MFL65-D1/130-E2 dual seal

Download the solution flyer

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.

Cruise liners have to reduce their sulfur emissions in Emission-Controlled Areas (ECAs). To accomplish this, light fuel oil is used in coastal regions - with significant consequences for the ship's fuel supply.