SITUATION

Canan Kozmetik, a sub-brand of L’Oréal based in Istanbul, faced a long period of constant downtimes and high maintenance costs due to seal failures.

Canan Kozmetik, a sub-brand of L’Oréal based in Istanbul, faced a long period of constant downtimes and high maintenance costs due to seal failures.

The production of hair wash products can be a great challenge for cosmetics companies. A variety of raw materials with different physical and chemical properties has to be processed.

A solution was found by experts from EagleBurgmann in the form of cartridge seals with the innovative DiamondFace® Technology.

Whether it’s for more volume, for more sheen, for dyed hair or for a well-groomed beard – the choice of shampoos seems practically endless nowadays. Only few people ever think about what happens before their favorite product is placed on the supermarket shelf. The production of hair wash products can be a great challenge for cosmetics companies. A variety of raw materials with different physical and chemical properties has to be processed. Canan Kozmetik, a sub-brand of L’Oréal based in Istanbul, faced a long period of constant downtimes and high maintenance costs due to seal failures. A solution was found by experts from EagleBurgmann in the form of cartridge seals with the innovative DiamondFace® Technology.

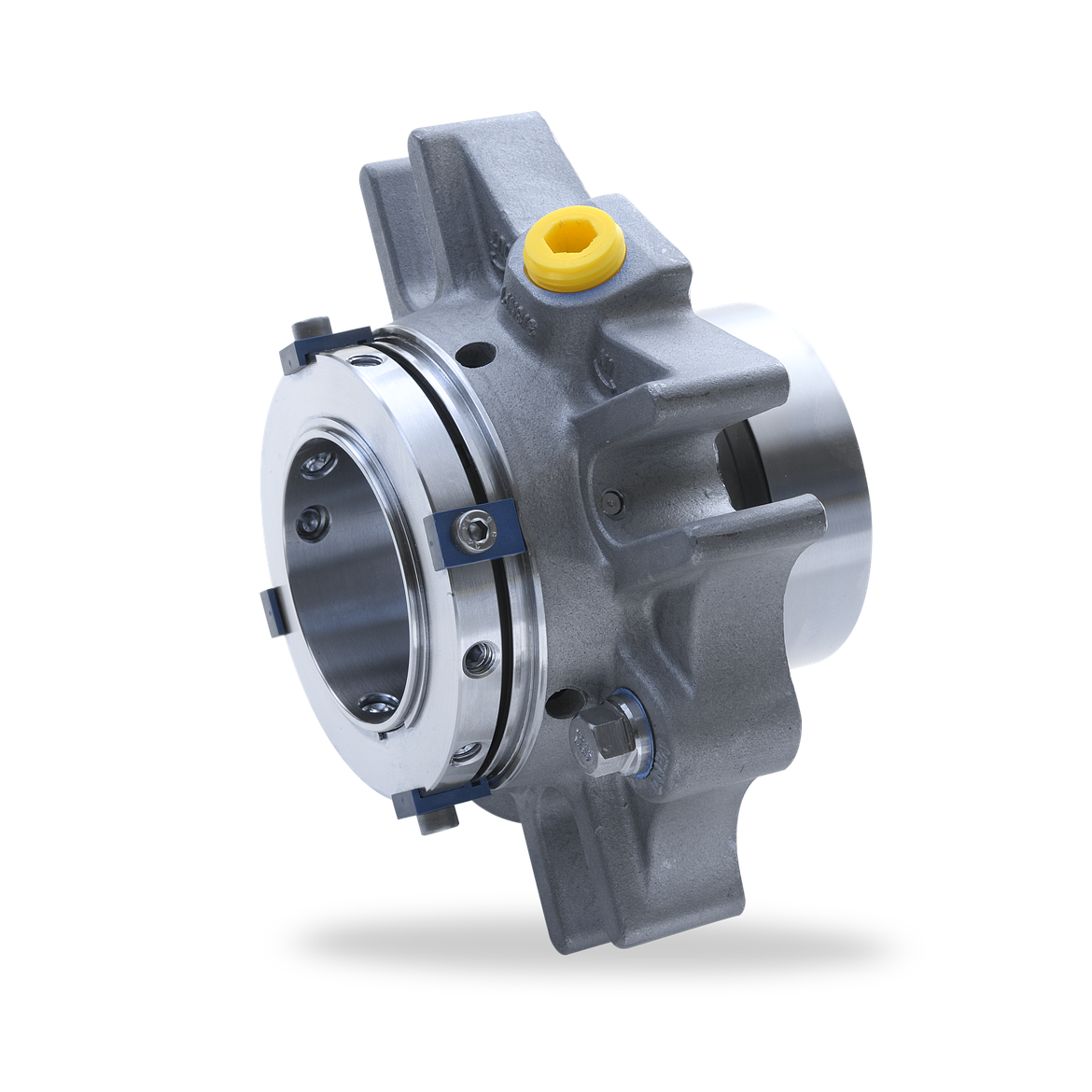

Cartridge seals are ready-to-install seal cartridges in which all parts of the mechanical seal including the shaft sleeve, casing parts, connection flange and torque transmission form a compact unit.

While the base of all shampoos consists of 70 to 80 percent water, the additional ingredients reflect the diversity of advertising claims we can find in the supermarket shelf. Apart from surfactants which provide the actual cleaning effect, there are for example nurturing ingredients and conditioning agents to improve the ease of combing. Different additives and preservatives as well as colorants, pearl shine concentrates or opacifiers complete the formulations. Turning the different ingredients into a homogenous mixture is generally challenging due to the diversity of substance properties. Surfactants for example are highly viscous liquids. Zinc pyrithione, which is used to fight dandruff, is a solid material. It is insoluble in water and only starts disintegrating at 240 °C. The most-known ingredient is actually table salt (sodium chloride), which is used as a thickening agent.

Canan Kozmetik used three mixers in the early stage of shampoo production to process a formulation which contained three to four types of salt and powdery materials. During the mixing stage, drying steps were also performed. Under these conditions, the mechanical seals used to seal the mixing vessel against the electrical drive failed regularly. “The lifespan of the seals was very short. On average they ran for only two months”, explains Serkan Celikbas, sales executive at EagleBurgmann who was responsible for the project. The seal failures entailed serious consequences – liquid leaked from the mixing vessels into the rotor unit and caused damage to the bearings and the electrical engine. “The machines can’t be disassembled. Thus, the whole rotor unit had to be sent to the manufacturer for repair every time the seals failed. Apart from high maintenance costs, the consequences also included extended production downtimes and the customer was extremely dissatisfied with the machines and the seals”, Celikbas remembers.

Canan Kozmetik approached EagleBurmgann with their problem as they had already made positive experiences in the past. “I’ve been in charge of this customer for five years now”, Celikbas states. “During this period, we were able to assist the customer with successfully completing different projects. Hence, in March 2017 they invited us to take a look at the problem and find a solution.”

The experts of EagleBurgmann quickly discovered the main problem. The customer couldn’t prevent regular dry running of the seals during the process. Usually mechanical seals are automatically lubricated by the processed product. When they run dry, the seal faces heat up to temperatures of more than 300 ° C due to friction. “The factory installed mechanical seals were not designed for such operating conditions”, amplifies Yigit Orkun, sales engineer in the same team as Serkan Celikbas. “The material of the seal faces was not able to sustain the temperatures and failed. Additionally, the solid particles within the mixture damaged the seals.“

EagleBurgmann found a solution for Canan Kozmetik which guarantees a longer lifespan of the seals and simplifies maintenance. “We offered them cartridge seals for quick and easy installation and which also prevent extended downtimes for maintenance works.” Celikbas explains. “Furthermore, we recommended choosing seals with seal faces which have been treated with our DiamondFace® Technology as they suffer fewer problems from dry running and are more robust against solid particles.”

A service technician from EagleBurgmann installed the first eCartex type seal at Canan Kozmetik in October 2017. “In terms of assembly and disassembly of mechanical seals within different machines, our team has a great deal of experience and knowledge. Therefore, we often conduct the first installation to make sure everything works properly”, Orkun states. Afterwards, the performance of the seal was observed carefully by EagleBurgmann with weekly visits at the customer’s site.

„We are very satisfied. Thanks to the eCartex seal, the machine runs without any problems”, says Tanju Toral, Manufacturing Supervisor at Canan Kozmetik . “In July 2018, the second machine was retrofitted. The third retrofit is currently in the planning phase.” The solution also allowed the customer to reduce dependency on external service technicians. “Due to the easy installation of the cartridge seals, we were able to train our own technicians to change the seals”, Toral adds.

Thanks to the solution provided by EagleBurgmann, a seal which needed to be replaced every two months could be exchanged with a product which has now been running reliably and faultlessly for several years. The slightly higher investment costs for seals with DiamondFace® Technology compared to the previous product thus amortized very quickly

The innovative DiamondFace® Technology was developed in 2007 by EagleBurgmann, the Fraunhofer Institute for Surface Engineering and Thin Films (IST), the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS), the Fraunhofer Institute for Mechanics of Materials (IWM), the Condias GmbH and the Forschungszentrum Jülich. The technology behind it is a microcrystalline diamond layer up to 15 μm thick which is applied to the seal face under vacuum at temperatures of 2,000 °C (3,632 °F) by chemical vapor deposition (CVD). The properties of this diamond layer are extreme hardness and wear protection, excellent thermal conductivity, chemical resistance and low friction values.

Advantages: DiamondFace® Technology

• Up to 80 % reduced energy consumption and minimized heat development

• Improved process reliability due to optimized dry running capacity

• Universally applicable, even for high concentrations of solid particles within the process media

• Up to 100 % prolonged operational life, extended MTBF and MTBR intervals

With the eCartex seal, EagleBurmann offers an off-the-shelf cartridge seal with DiamondFace® Technology. The eCartex is available in all common sizes within 24 hours.

Operating conditions

• Temperature: 70 – 80 °C

• No Vacuum

• Speed: 1,500 rpm

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

By means of custom-made PLUG & RUN expansion joints with a more wear-resistant material, EagleBurgmann was able to provide a solution which ideally fulfills the requirements with regard to wear while at the same time significantly reducing the changeover time.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

Special expansion joints from EagleBurgmann compensate for these position changes and work reliably even under unfavorable conditions such as low temperatures, proximity to the sea and explosive environments.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.