Situation

Boiler feed pump in a nuclear power station in southern Germany

DF-SAF(P)I seals as a solution against electrical corrosion

Boiler feed pump in a nuclear power station in southern Germany

Complicated repair jobs and expensive downtimes due to destructive electrical corrision

EagleBurgmann mechanical seals DF-SAF(P)I with DiamondFace

Ever since October 2010, the world‘s first mechanical seal with diamond-coated sliding faces has been operating in a boiler feed pump at a nuclear power station in southern Germany, to the complete satisfaction of the operator, E.ON. EagleBurgmann is the first and only company to offer this convincing technological solution which has currently been used in the SAF(P)I seal type.

Illustr.: Boiler feed pump at the power station operator E.ON, equipped with EagleBurgmann DF-SAFI.

The outstanding advantage of the DF-SAF(P)I is that it puts an end to the electrical corrosion that has a destructive effect on the silicon carbide rings. Even without conditioning the feed water, e.g. by injecting ammonia, the seal with coated seal face and seat achieves a significantly longer service life. Complicated repair jobs and expensive downtimes are both minimized as a result.

Before the DiamondFace coating was used, it was tested under scientific conditions and with the original fluid as part of a project undertaken jointly by EagleBurgmann and the Technical University of Graz in Austria. After more than 10,000 hours of continuous operation without any signs of electrical corrosion on seal face or seat, it was then possible to go on to successful practical application of the seal solution together with E.ON.

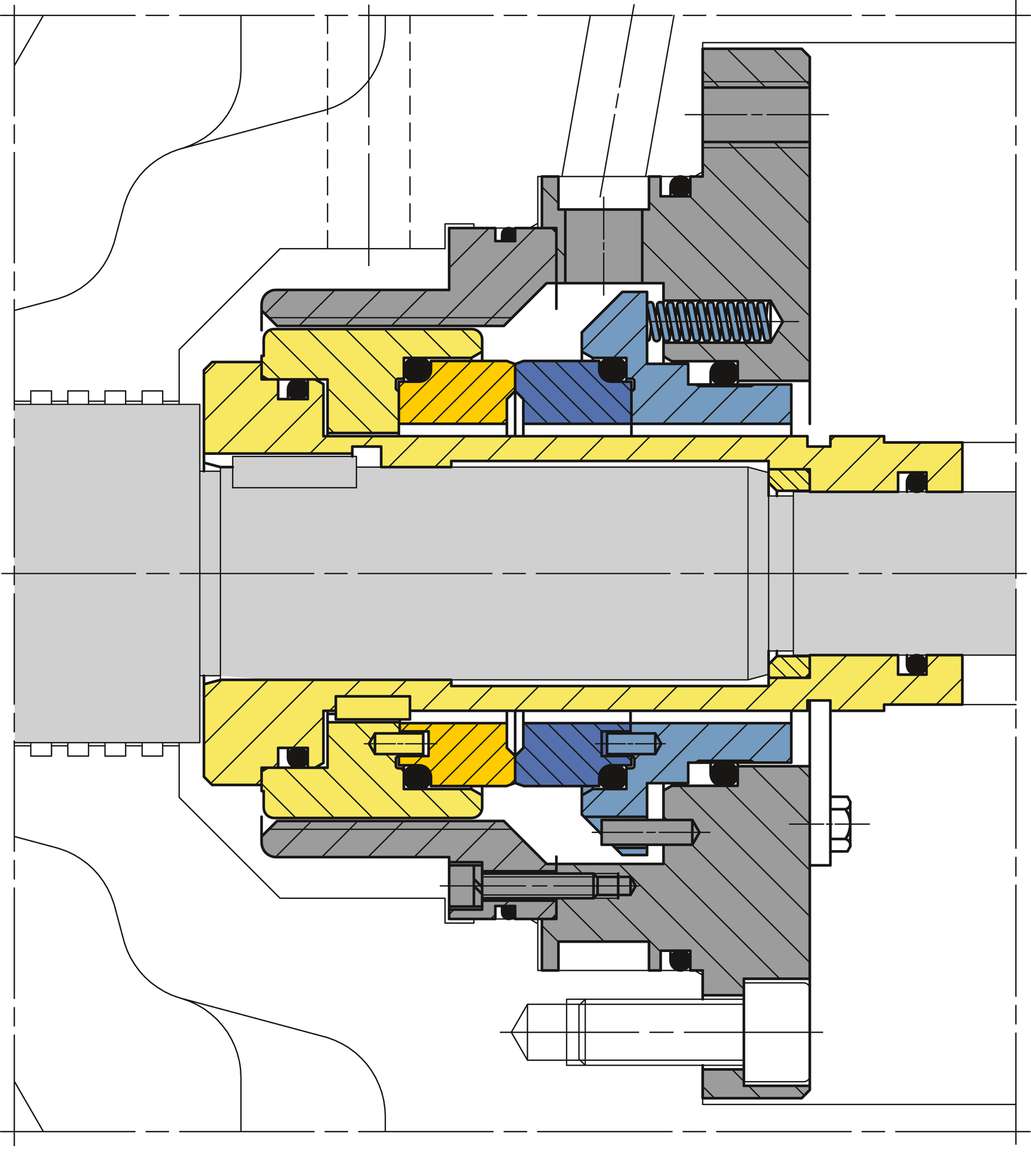

Illustr. 1: Mechanical seal type DF-SAF

Illustr. 2: Yellow parts = rotating, blue = stationary, gray = housing

The operator‘s expectations were met in full, and as a result he ordered additional DiamondFace seals for re-equipping another pump. In the meantime, orders for power stations operated by other customers in the USA, South Korea and Switzerland had been placed and completed. Reports on the experience at EagleBurgmann's reference customer, E.ON, were one of the decisive factors leading to these decisions.

EagleBurgmann has been working successfully and in a spirit of partnership with E.ON for more than 20.years, to the mutual benefit of both partners. This confirms that EagleBurgmann's success is determined not only by innovative technology but also by the commitment and customer orientation displayed by its employees.

Download the solution flyer

Download the brochure

Learn more about our diamond-coated high-performance DF-SA seal

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

A boiler circulation pump in a power plant conveys very hot and pressurized water. The pump has no cooling jacket, which increases the risk of a thermosiphon effect.

By means of custom-made PLUG & RUN expansion joints with a more wear-resistant material, EagleBurgmann was able to provide a solution which ideally fulfills the requirements with regard to wear while at the same time significantly reducing the changeover time.

Mechanical seals are not always the best choice. In roller dryers used in the production of pharmaceutical powder, abrupt shaft deflections during processing led to increased seal wear. Operation was maintenance-intensive and prone to faults.

Special expansion joints from EagleBurgmann compensate for these position changes and work reliably even under unfavorable conditions such as low temperatures, proximity to the sea and explosive environments.

The Etzel oil and gas cavern system is situated southwest of Wilhelmshaven, not far from the North Sea coast. A vast salt dome houses the more than 70 caverns which store crude oil and natural gas at depths between 900 and 1,700 meters. Etzel is integrated in the northwest European oil and gas pipeline network and makes a significant contribution to the safe and reliable supply of gas to Germany and all of Europe.